PI System Automation has a solution for all your automated handling issues.

Based on your requirements, we research, create and integrate automated handling systems.

We offer you a global solution which combines equipment performance, personnel safety and component durability.

Via our experience in the individual load handling sector we can handle numerous applications:

We design and make conveyors specially adapted to bulk handling:

In order to enhance its heavy product handling offer (1t to 1.5t), PI System Automation has developed the S’link range, specially adapted to the automated transfer of pallets at the end of line.

Innovations and commitments that make the difference

We can deliver our equipment prewired. A standard or customised diagram in different file formats will be provided to connect you to terminals, drives, cells and sensors.

This will save you a huge amount of time during setup and you will be able to prepare the connection before installation. This is particularly relevant to the S’TURN turntable or the S’CROSS transfer where it is difficult to access sensors and actuators because of the compactness of the parts.

The START & ROLL technology is accessible and configurable for everyone and can accommodate our S’ROLL 1500+, S’CHAIN and S’TURN products.

As well as supplying you with prewired equipment, we also offer you the option of installing and defining its operating mode yourself with additional automation hardware. Lastly, we offer you the safety option of separate wiring.

For example: on all our turntables, our optional commutator can be coupled with the terminal connection in order to obtain a standard rotation of not just 90° but 360°.

We guarantee all our equipment for 24 months against manufacturing faults or material defects. This is within the context of normal operation, including the date of delivery on site.

Bringing your business peace of mind.

We ensure availability of spare parts for our products to avoid unnecessary storage.

In addition, we target so-called standard equipment with a set of common parts. Therefore the rollers used on the S’ROLL 1500 are identical to those used on S’TURN, S’CROSS, S’TRANS and S’ELEV products.

That means you have the same type of spare roller to install on all your modules that make up your installation.

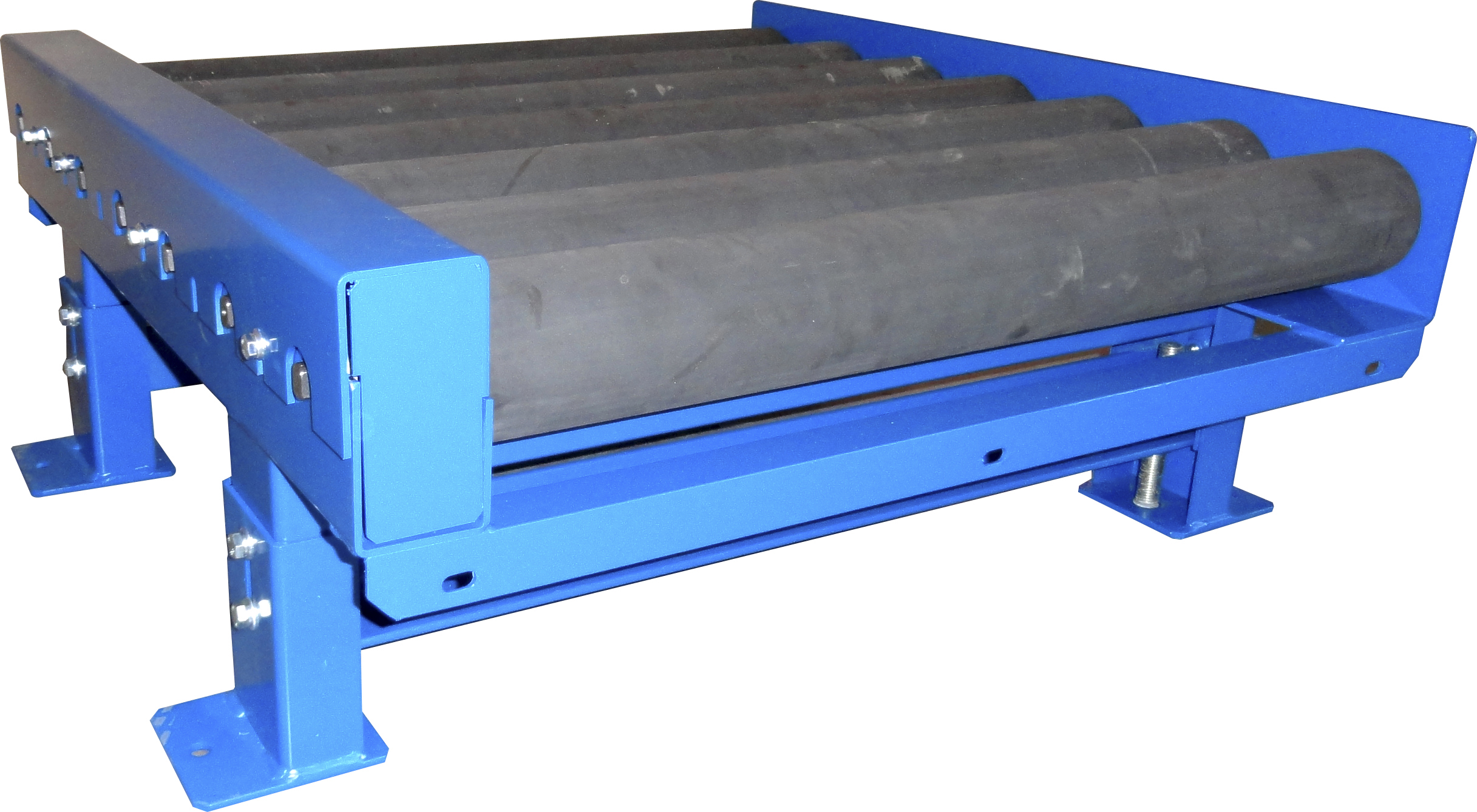

S’roll

Manage the handling of full pallets, lengthwise

89X3 rollers have 150mm treads. Transfer level on roller HR=500mm and standard adjustment ± 50mm (from 450mm to 600mm is possible). Base length = 1350mm. Max. length = 6000mm (4 x 1500kg pallets)

10m/mn as standard (from 6 to 15m/mn possible)

SEW Usocome or equivalent, 230/400V with 400V brake, IP54 class B protection. The drive is located under the chassis

S’chain

Manage the handling of full pallets, widthways.

Basic module 1g = 1350mm, the length can be adjusted by 12m in 1 section. Standard feeder height = 485mm.

10m/mn as standard (from 6 to 15m/mn possible).

SEW Usocome or equivalent, 230/400V with 400V brake, IP54 class B protection. Drive located within the left gantry as standard (other locations are available, refer to the data sheet).

Double chain: up to 1000kg per pallet. Triple chain: up to 1500kg per pallet. Max. load limited to 6000kg.

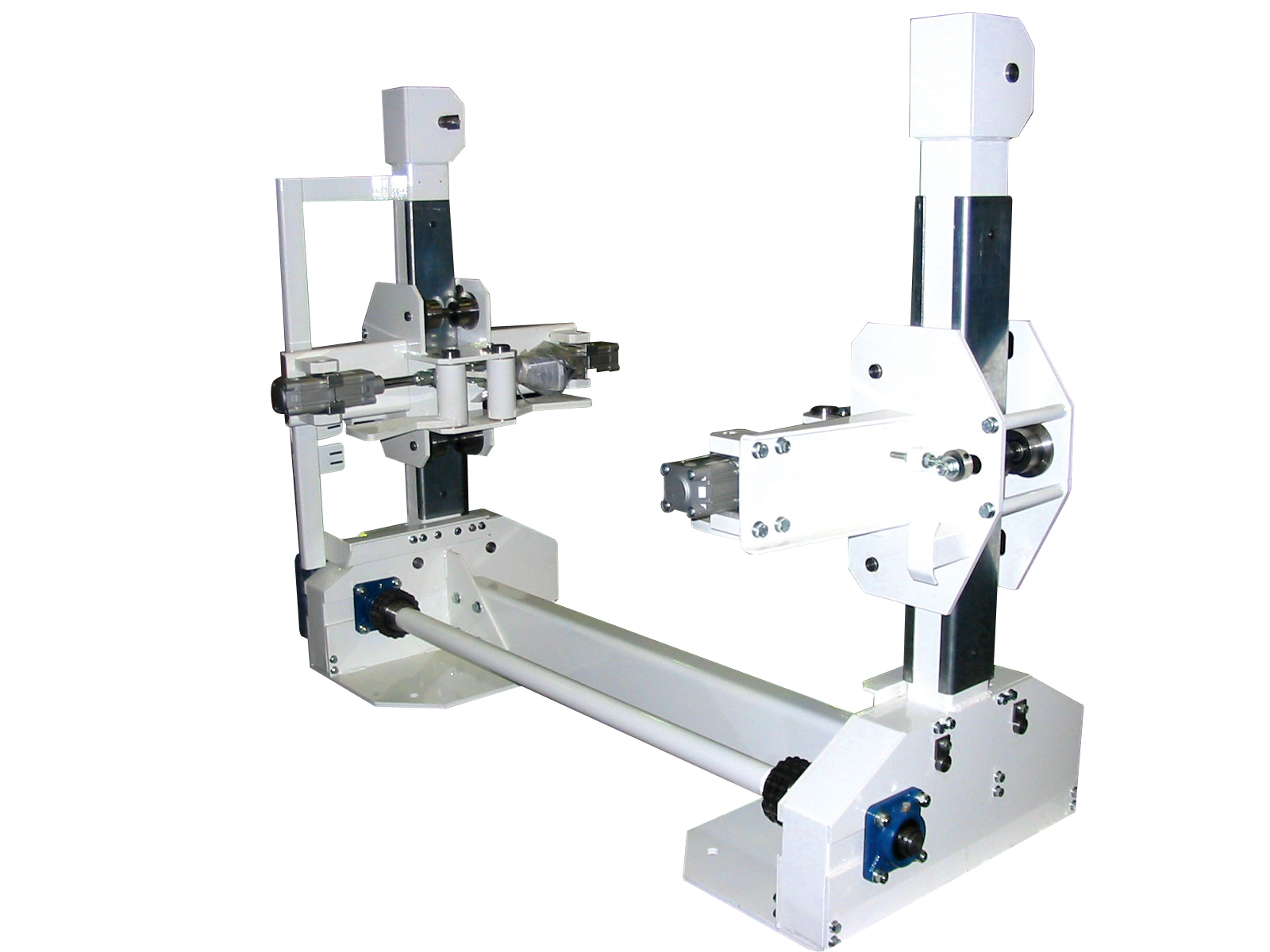

S’turn

Change the transport direction by +/- 90° without changing the orientation of the pallet in relation to its direction of movement.

Turning part fitted with a roller module or a triple chain module. The stationary assembly includes a rotation control system, shared by the ROLL and CHAIN applications.

10m/mn as standard (from 6 to 15m/mn possible). Standard rotation = 8s for every 1/4 rotation

SEW Usocome or equivalent, 230/400V with 400V brake, IP54 class F protection for rotation control.

Rotation is managed by a coil with a slewing bearing, controlled by a pinion module driven by a ring and pinion gearbox

S’cross

Manage the change the direction by +/- 90° by changing the scrolling orientation of the pallet in relation to its direction of movement.

Basic module with rollers, equipped with a system raised and lowered by eccentric cams, controlled by a gearbox, either integrated in the double or triple chains, of with integral double or triple chains. Levelling detection via 2 Ø18mm inductive sensors.

Feeder on rollers V= 10m/mn as standard (from 6 to 15m/mn possible). Feeder on chains V= 10m/mn as standard (from 6 to 15m/mn possible). Elevation time = 6s as standard

SEW Usocome or equivalent, 230/400V with 400V brake, IP54 class B protection

S’trans

Manage the distribution of loads between different conveyor parallel lines via linear movement.

Self-propelled chassis fitted with a basic module with powered rollers or a basic double or triple chain module. Monorail guide system to embed in the ground.

10M/mn standard movement. Polyurethane tyre wheels to feed directly to the ground.

SEW Usocome or equivalent. 10M/mn standard movement.

S’elev

Manage the distribution of loads between different conveyors at different altitudes in terms of elevation.

Self-supporting structure including a basic module, with chains or rollers, integrated into a platform providing a connection between the various levels to stop at, vertically.

Basic hoisting = 8m/mn.

Class F 230/400V SEW Usocome with 400V brake, controlled by a variable frequency drive.

S’roll +

Manage the handling of full pallets, lengthwise.

1350, 1500, 2700, 3000 modules with 1 or 2 rollers depending on the number of required pallet locations.

8, 10, 12, 15m/mn.

DAVID 0.18 or 0.25kW powered roller in accordance with the feeder speed with is load accumulation management logic communicating with one module to another.

S’stacker

Manage distribution on a conveyor of a stand-alone pallet starting from a stack or reform a pile of pallets by supplying the pallets unit by unit.

Pallet handling using 4-finger PCV sensors controlled by Ø50 cylinder with 80mm stroke. Levelling detection via 3 Ø18mm PNP NO inductive sensors, short steel unit, 8mm sensing distance. Transfer level on rollers HR = 500mm as standard (from 450mm to 6mm possible) ± 50mm adjustable

Elevation via SEW USOCOME brake motor or 0.37kW equivalent IP54 class B protection, for 15 pallets or 500kg

Copyright @ 2018 - Blizz - Legal Notice